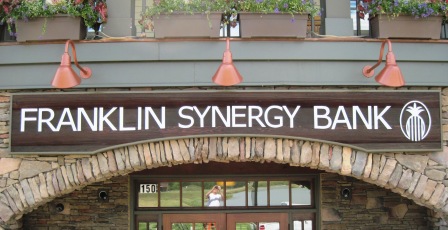

Sandblasted redwood is a classic, handcrafted look that is acheived through a multiple step process. The first step is choosing the right wood; one of the best woods to use for sign longevity is clear all-heart redwood, which means the facings are clean and free of knots. This makes for an exceptional piece of wood to work with. Once the piece is chosen, it is custom routed to the desired/designed shape, and then a digitally cut rubber masking is created to cover all the non-blasted areas. The sign panel is then taken to the sandblaster, where fine sand is forced through a tube at high speeds to wear away the areas not protected by the masking.

Once the desired areas are sandblasted, the masking is removed, leaving all the masked surfaces raised and the background recessed and textured to the desired look. The redwood sign is then primed to create a proper barrier from the elements to withstand outside applications. Once primed, (or sealed, if you would like the natural wood look) the sign can also be painted. In the paint stage, the sign will be finished with exterior-grade paints, adding the desired colors and themes to the fabricated sign. The fabricator masks and paints specific areas with the chosen colors to finish off the sign's appearance.

Once the panel is finished, it is mounted in several different ways. One way is to be mounted to posts on either side via metal bracket hardware, where the posts are then sunk into the ground a minimum of 18-24" for support strength. Another option is a hanging arm sign, where the vertical post is contructed with a cross member, and the sign panel is fastened to it via "S" or "eye" hooks and hangs from the arm. And finally, using several different cleat-inspired hardware solutions, the sign can be mounted directly to the building or exterior surface, flush mounted or floated off with spacers to add one more dimension.

Leave a Reply