Are y'all ready to be blinded by some science?

Forgive the graininess of the picture—this music video was filmed 32 years ago, after all!

Forgive the graininess of the picture—this music video was filmed 32 years ago, after all!

We use acrylic panels all the time for our various acrylic signs and projects. It's a great material for lots of reasons (which we've written about), but particularly because it's cost effective, light weight, virtually weatherproof, and easy to install.

Acrylic is a type of plastic that has at least one derivative of acrylic acid in it. Polymethyl methacrylate (PMMA) is the most common type of acrylic plastic and is highly resistent to UV and weather damage. Common brands that vend PMMA acrylic are Plexiglas, Lucite, Crystallite, and Perspex. Like all plastics, acrylic is a polymer.

The word "polymer" comes from two Greek roots: "poly" meaning "many," and "meros" meaning "part." Some have compared the way acrylic is made to tossing broken glass, copper, and other parts in a carboard box, shaking it up, waiting an hour, and coming back to find a working color television. Basically you start with a lot of seemingly unrelated elements, heat them up and wait a bit, and you get something completely different in the end. In this case, the "many parts" that make up acrylic are molecules chainlinked together to create a strong bond.

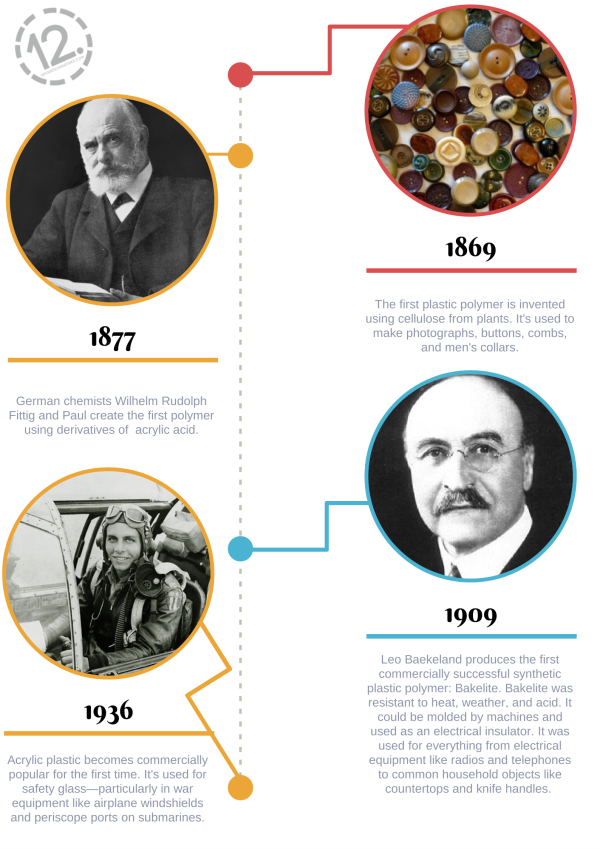

A Brief History of commercial plastics

Today, acrylic can be used for everything including furniture, clothing, windows, glasses and, of course, signs.

How it's Made: Bulk Polymerization

Acrylic is made by combining a monomer (monomers are molecules that can bond to identical molecules to form a polymer) and some sort of catalyst like an organic peroxide or alcohol. Acrylic can be formed in flat sheets, rods and tubes, or into a molding powder, but we really only use the sheets for our purposes. The sheets are formed through a process called bulk polymerization. There are two ways acrylic can be formed through bulk polymerization: batch cell and continuous.

Batch cell bulk polymerization:

1. Manufacturers use a rectangular mold using either two metal or glass sheets separated by a flexible spacer called a "window-frame." The flexiblility of the spacer allows the inside of the mold to shrink as the materials contract during the polymerization process. Oftentimes plates and spacers are stacked on top of each other with the top of one mold becoming the base of the next mold so they can manufacture many at once. The sheets and window-frame are held together using spring clamps.

2. A syrup made of a liquid mixture of the methyl methacrylate monomer and a catalyst is poured into an open corner of each mold until the mold is filled up.

3. The mold is sealed and heat may be applied to hasten the reaction process.

4. Because the reaction process will create heat, the molds are either placed in air ovens or water baths to control the temperature. Manufacturers will have programs in place as the molds cure to control the temperature of the acrylic to prevent bubbles from forming in the plastic.

5. After the acrylic has cured (thin sheets take anywhere from 10 to 12 hours to cure, while thicker sheets may take days), the acrylic is cooled and removed from the mold. The glass or metal sheets are then cleaned for the next batch.

6. The acrylic can then be either used as-is or annealed (heated and then slowly cooled) to strengthen the material and fix any warping.

7. "Flash" (excess material) is trimmed off and the surface of the acrylic is covered in masking tape or a plastic film to protect it during packaging and handling.

Continuous Bulk Polymerization:

1. This process is similar to batch cell polymerization, but the sheets are much thinner so the production time is greatly reduced. Much like a factory line, these acrylic sheets are made on stainless steel belts.

2. The syrup mixture of the monomer and catalyst is poured in between the stainless steel sheets, that have been spaced according to the desired thickness of the acrylic.

3. The belts hold the mixture together and move it through a series of heating and cooling cycles to cure the polymer.

4. Some manufacturers may use hot air or other electric heaters to anneal the plastic at the end of the cycle.

5. The sheets are then cut to size and covered in protective film or masking tape.

We leave as much of the protective film on acrylic signs as we can while we work on them to prevent scratches or oils from fingerprints from getting on the sign's face.

We leave as much of the protective film on acrylic signs as we can while we work on them to prevent scratches or oils from fingerprints from getting on the sign's face.

So, friends, now you know how acrylic is manufactured! You now have something to talk about at boring dinner parties and a possible answer to a question on Jeopardy. :)

Sources: How Products are Made, Plaskolite Inc., howisitmade.org

Interested in your own acrylic signage? Click the button below to get a free quote and consultation from a 12-Point SignWorks signage expert!

Leave a Reply