When we think of vinyl wraps, we typically imagine the smooth, sleek surface of an exotic Maserati, Bentley, Aston Martin, or maybe a Nissan GT-R. Even though the wrap creates a stunning, paint-like finish on these vehicles, vinyl also can be used for rough, textured surfaces. The end result may not be as sleek as that of a smooth surface, but the material conforms to the rough surface as if it's been applied with fresh paint.

Textured surfaces, including brick, stucco, and concrete, are found all around us. Areas include:

- Retail stores

- Stadiums and arenas

- Transit stations

- Convention centers

- Schools

- Public buildings

- Private businesses

- Entertainment venues

- Gymnasiums and fitness clubs

- Locker rooms

The graphics installed on the walls can feature promotional events, advertisements, motivational messages, school mascots, branding images, or even accents to the overall décor.

We installed the dark green lettering and adorable candy character to the painted masonry block wall of this retail location. The letters were placed high enough to be out of reach of curious fingers.

When we work with textured surfaces, we recommend that they are sealed or painted. This helps prevent moisture from interfering with the bond between the vinyl and the surface area. We use heat and apply pressure with a foam roller to install the vinyl. Vinyl film made for rough surfaces is conformable to the grooves and variations in contact points, and the heat helps the vinyl make contact with every nook and cranny (technical term). The foam roller ensures that the application is thorough and does not leave any gaps or bubbles. The material also has stronger adhesive to make sure that it's not going anywhere.

We use high-performance materials with a protective laminate to extend the life of the material. As for the durability of a wrap on a textured surface, it varies based on the environment in which it is displayed. Interior, protected wraps will probably last longer than exterior wraps exposed to the elements; however, contact from people passing by, on, or over the wrap will reduce its lifetime.

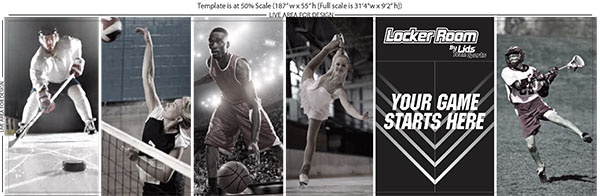

This is a proof for the LIDS Locker Room wall and door mural that we fabricated and installed at A-Game in Franklin.

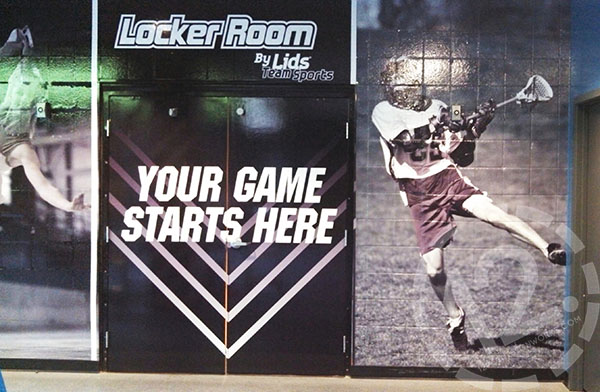

Here is a portion of the wall and the doors after the installation! The vinyl material was digitally printed with a protective gloss laminate. We installed it to the textured block surface, using heat and a foam roller. For the doors, we used heat and our trusted squeegees.

This photo shows another portion of the textured surface vinyl wrap for the LIDS Locker Room at A-Game.

If you are interested in a vinyl wrap on a textured surface, here are some things to consider:

- Painted/sealed surfaces work better. We recommend paint that is not low- or no-VOC. The paint needs at least two weeks to cure to ensure the best bond.

- If your surface area is not painted/sealed, a vinyl material with a more aggressive adhesive will be required. This could make the vinyl more difficult to remove.

- Always test the compatibility of the vinyl material to the surface you would like wrapped. (If you use a professional for the installation, they should do that for you!)

- Banners and other signage often require hardware to hang on to the side of a building. No hardware is needed for a vinyl wrap, which means no damage to the building.

If you are ready to stand out from the crowd, it's time to consider a specialty vinyl wrap for your textured surfaces. Take advantage of those previously ignored and drab cinder blocks, and add a creative and colorful design that enhances your business or surroundings. Often these areas are the perfect spot to highlight a product, increase team spirit, support local organizations, or strengthen your brand.

Contact us today at (615) 595-6564 or click on the button below to get started on your project!

Leave a Reply